Hydraulic Hose Preventative Maintenance for Hose LeaksĪ good hose inspection will always involve checking for leaks in the hose itself as well as at connectors and couplings. When hoses have been stretched too tight, they may burst at the fitting, but a careful inspection can catch that problem before it happens. Cracks, corrosion, and other damage to the connectors will inevitably lead to leaks, and the longer these issues are neglected, the more intensive the damage and repairs become.

Hose connectors are also inspected carefully during preventative maintenance. Hydraulic Hose Preventative Maintenance for Hose Connectors This might involve re-routing the hoses or use of a protective shield to prevent the same issue from arising again. It is also important to look for what could be causing the damage, such as a hose being run too close to a heat source or rubbing against a hard metal object during service. In all of these cases, a hose assembly replacement is needed immediately. Damage might also take the form of blisters, color changes, or hard spots. That could mean that the hose cover is cracked, cut, abraded, or split. Hydraulic Hose Preventative Maintenance for Hose Coversĭuring a hose inspection, the first thing a technician looks for is damaged hose covers. Technicians inspect hose covers and connectors, check for signs of leakage, and check hose routing as part of a solid inspection routine. Fortunately, there are quite a few warning signs for hydraulic hose failure.

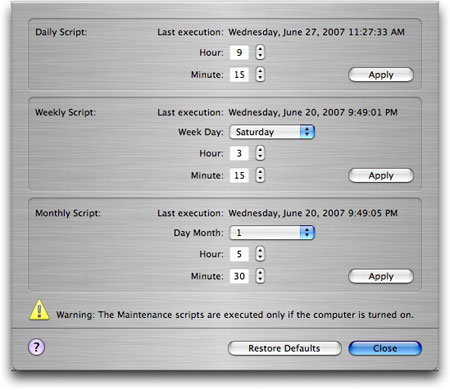

PREVENTATIVE MAINTENANCE FOR MAC HOW TO

Early Warning Signs of Hydraulic Hose FailureĪn experienced technician is aware of early warning signs of impending failure and knows how to address the issue. Hoses involved with critical equipment or extreme operating temperatures, for example, should be inspected more frequently.

There are, however, other factors that may come into play. In the case of mobile equipment, hose inspections should take place every three months or every 400 to 600 hours of use, whichever occurs first. Stationary equipment should be inspected about every three months. Part of a solid hydraulic hose preventative maintenance program includes the regular inspection of hydraulic hoses.

PREVENTATIVE MAINTENANCE FOR MAC MAC

However, if you do need a hydraulic hose repaired or replaced, MAC Hydraulics can do that as well. Not attending to regular preventative maintenance can be an expensive decision. Attention to maintenance also increases the life expectancy of the equipment and maximizes its economic value while minimizing safety hazards for personnel.įinally, preventative maintenance reduces repair costs and unnecessary equipment purchases. One reason is that it keeps your equipment working efficiently and productively by addressing problems before they fail and have a significant negative impact on the system.Ĭontrary to what many believe, preventative maintenance means less downtime due to unexpected part and system failures. Preventative maintenance is always better than reactive maintenance for hydraulic hoses and equipment in general. The more rigorous the hose inspection process is, the more reliable your equipment will be. This can include inspecting hose covers and fittings as well as looking for leaks and other signs of impending hose failure.

Hydraulic hose preventative maintenance is vitally important and involves regular inspection intervals in order to spot problems before they start. Hydraulic hoses are a key component of any hydraulic system, and when they fail, everything can come to a grinding halt.

0 kommentar(er)

0 kommentar(er)